Filling Feature

- The tolerance of filling liquid level is below 2mm,better than the industry standard.

2. The advanced technology of frequency conversion speed regulation is adopted on the machine,and the largest filling volume will get to 200-300 bottles per hour.

3. Bottle height is from 140-340mm,easy to adjust.

4. Tight seal,and it does not fill if there is no bottle or bottle broken.Liquid flows down along the inner wall of the

botlle,effectively control of the foam and spill.

5. It is widely used for red wine,fruit wine,flavoured drinks,sauce-soy,vinegar etc.

6.The spiral bottle arranging device ensures the safety of the bottle-feed-in.

12 heads filling machine

12 heads filling machine

1.With glass housing to protect

2.With CIP cleaning system

3.With pump for auto-liquids-supplying

4.With conveyor line easily working

5.With filling valve for the same liquid-level

- Accurate filling liquid level2. High working efficiency

3. Large range of bottle adjustment

4. No liquid loss,no drip dropped

5. Large range of applicaton

6.Free bottle-feed-in

12 heads filling machineThere is bottle feeding in Screws and Starwheels which make bottle moves steadily.

Filling Valves with new Design

Low vacuum filler is recommended for still,non dense liquids such as still water,wine,alcoholic beverage

(whiskey, vodka, brandy etc) and any kinds of flat non viscous liquids.In this case,the opening of the filling valve is given by the neck finish of the containers,lifted by the mechanical plates of the filler. wine,alcohol beverage automatic filling machine with high precision.

Filling line for test before shipping

Magnetostrictive sensor controlling the

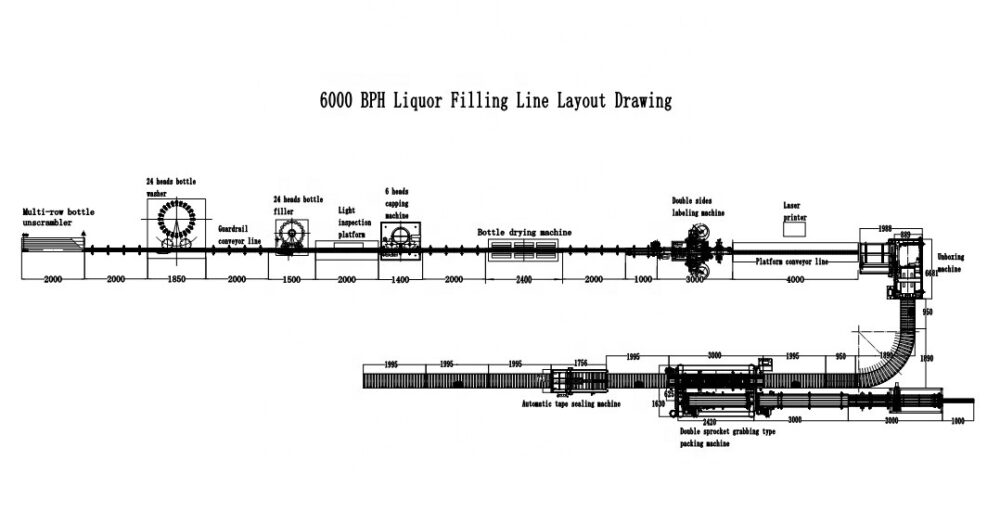

liquor filling line layout drawing

the whole process bottles Depalletizer,unscrambler,feeding,washing,filling,t corking,capping,sleeve shrinking,labeling and packaging stage

Filling Samples Application

|

Model

|

Filling Heads

|

Capacity bph

|

Bottle Height mm

|

Bottle Dia. mm

|

Filling Tolerance ml

|

Power kw

|

Dimension

mm

|

|

GFP-12

|

12

|

2000

|

140-320

|

≤100

|

±0.5%

|

0.75

|

1200x1050x2100

|

|

GFP-18

|

18

|

4000

|

|

0.75

|

1300x1180x2100

|

||

|

GFP-24

|

24

|

6000

|

1.5

|

1700x1450x2100

|

|||

|

GFP-30

|

30

|

8000

|

1.5

|

1900x2000x2100

|

|||

|

GFP-36

|

36

|

10000

|

2.2

|

2300x2150x2100

|

|||

|

GFP-40

|

40

|

12000

|

2.2

|

2300x2300x2100

|

|||

|

GFP-48

|

48

|

14000

|

3

|

2600x2700x2100

|

|||

|

GFP-60

|

60

|

16000

|

3

|

3300x3300x2200

|

1.Monoblock of Rinser Filler Capper/Corker

- High efficiency to get to 2000 bph capacity.

- Large application range.

- To keep the same liquid filling level.

- No bottle leakage.

- No bottle no sealing.

2. Washing Machine

- Rinse thoroughly-bottle inside and outside clean by water or chemical liquids.

- Adapt to bottle type,It is suitable for various bottle types with wine bottle height 140-300mm and bottleneck ɸ25mm-ɸ100mm.

- Water saving: Equipped with a circulating water tank, which is used after water filtration to reduce water consumption.

- Wide adaptability.

3. T Corking Machine

1.Mainly used for T-cork cap in glass bottles. 2. There is push-down part before capping. 3.Equipped with T-cap feeding device, automatic arranging corks, labor saving and reliable. 4.Equipped with photoelectric sensor system, no bottle no cork.

4. Aluminum Capping Machine for refrence

- The capper is suitable for aluminum screw caps: ropp cap,sleeve,stelvin caps

- This capper can be customized based on customer’s requirement.

5 Automatic Corking Machine for reference

1.Mainly used for soft wood cork in glass bottles. 2.The shrinkage cork mechanism adopts an independent squeeze head to ensure the

smooth progress of the cork. 3.Equipped with arranging device, automatic arranging corks, labor saving and reliable. 4.Equipped

with photoelectric sensor system, no bottle no cork.

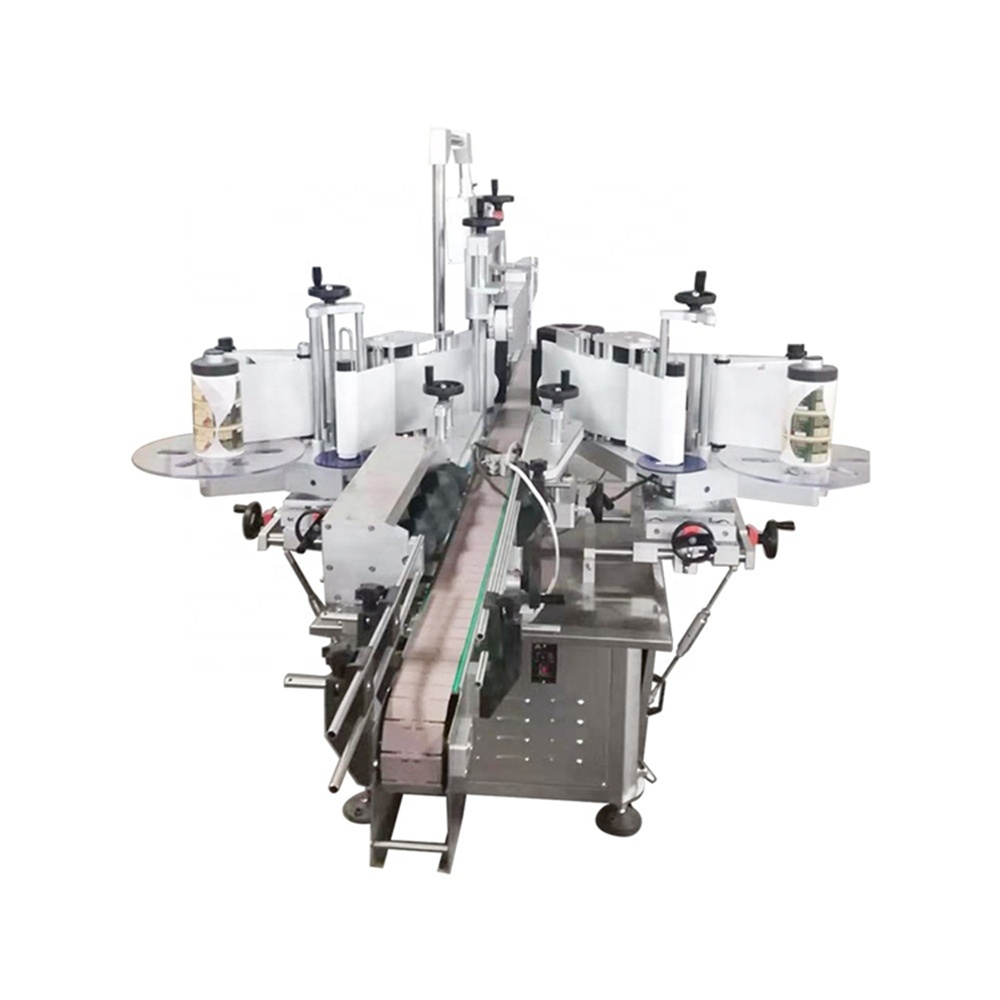

The labeling part

1.Adopts the original pneumatic roller structure. 2. High repeat accuracy, no bubbles when labeling 3. This machine is especially suitable for high-requirement all-round labeling. 4. One or two labels can be selected for one-time labeling. 5. Real man-machine interaction, simple operation, online help information.

Reviews

There are no reviews yet.